3D Printing For Orthopaedic Surgery

Three-dimensional (3D) printing is an increasingly evolving technology with the potential to offer significant contributions to surgical practice. This is a type of manufacturing process in which materials such as plastic or metal are deposited in layers to create a 3D object from a digital model. Even though this process was born about three decades ago, only in recent years has 3D printing started to become widely known in both surgical and non-surgical worlds.

Today, as surgeons and researchers continuously utilise the technology’s flexibility in manufacturing objects, 3D printing has become more prevalent in medical applications over the last decade, giving surgeons a realistic physical model of the anatomy upon which he or she will operate. As the costs have come down drastically, 3D printing has started to have an emerging role in some medical fields, such as dentistry, orthopaedics and traumatology.

Orthopaedics has been among the first medical fields to use 3D printing. Orthopaedic surgeons use it in their clinical practice for patient-specific orthopaedic applications. 3D printing technology has reported to be beneficial in patient-specific orthopaedics as it can enhance patients’ understanding of their pathology and preoperative planning as well as the creation of anatomic models for surgical planning, education and surgical training, patient-specific instruments, and 3D-printed custom implants. The huge number of possibilities offered by this technology in various fields has defined 3D printing as the third industrial revolution.

3D printed models not only reduce the rate of re-operation but plays a vital role in surgical planning and in the training of novice surgeons.

How does it work?

In order to gain a more informative overview of the anatomy and to improve the detail of planning, the application of 3D printing has spread increasingly over the last few years which includes the use of a 3D printed model to assess the surgical approach for corrective osteotomies.

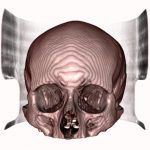

First, an image portraying the desired object must be collected. The surgeon then creates a virtual 3D model of the target anatomy from a series of bi-dimensional images by adding successive layers of material, translating the information contained in CT images into a more usable format.

The usual DICOM file format of the radiological scan data must be converted into a file format identified by the 3D printer. The DICOM file is uploaded into a program that allows the 3D reconstruction of the image. The file is exported in the stereolithography format that makes it readable to a computer-aided design (CAD) software used to design the 3D objects. The design is then sent to the 3D printer.

What are the benefits?

Apart from relying solely upon the use of CT, MRI data or virtual reconstruction, the use of 3D printed models offers a lot of distinct advantages to orthopaedics surgery. First of all, doctors and surgeons can use 3D printed models to explain to patients or students the details of a surgery or to practice the surgery itself.

With 3D printing technology, surgeons can now examine patient anatomy in a more concrete way and allow for improved, more detailed surgical planning compared with the traditional 2-dimensional radiological images. Pre-operations can also be made on plastic models which can be a fundamental aid in the placement of screws or surgical plates, in order to visualise the final outcome of the intervention.

Medimodel is the Medical Imaging Research department of Ignitec Technology Centre. Our mission is to help make surgery safer by putting physical models of patient anatomy in the hands of surgeons. Call us on +44 (0) 117 325 8171 if you would like to discuss your case with us.