The uses of 3D printing in planning orthognathic surgery

Introduction to 3D printing in orthognathic surgery

During any type of surgery models are important for treatment planning because they allow the surgeon to visualise the pre- and post-operative positions. An example of such surgery is orthognathic surgery – realignment of the jaws to improve the bite and facial aesthetics (Lin, et al., 2018). 3D printing in orthognathic surgery involves the use of CAD/CAM technologies for the precise fabrication of patient-specific models for planning the movement of the jaws during surgery. After treatment planning has been completed 3D printing can also be used for the fabrication of surgical splints for use during surgery.

How are models for 3D printing in orthognathic surgery produced?

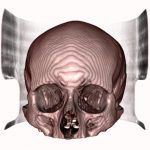

Data is created during scans, such as magnetic resonance imaging (MRI) or computed tomography (CT) and create 2D DICOM images which are incompatible with computer aided design (CAD) and computer aided manufacturing (CAM). After the scanning is completed CAD software converts the information into a digital file such as STL. With the information an existing object can be replicated with addition printing, or the image may be altered using CAD.

CT cannot create a sufficiently detailed image for the occlusal plane and intra-oral digital scanning can create a detailed intra-oral image. Alternatively, traditional alginate models may be taken and the resulting stone models may be scanned.

How are the models used in treatment planning?

Traditional orthognathic surgery planning involves using alginate impressions and a facebow record to articulate casts. Cephalometric (radiographic) analysis in used in conjunction with the surgical simulation with the models to create the desired postoperative position. Once the optimal postoperative position has been determined, a surgical splint is produced. The purpose of this splint is to record the position of the teeth in the upper and lower jaws, relative to each other.

3D printing in orthognathic surgery planning uses technology to enhance the treatment planning process. 3D scanning and printing creates preoperative models of the teeth and bones of the face. Surgical simulation is performed using the dental models to create the desired postoperative position.

The modified models are used to produce a surgical splint. Digital scanning and 3D printing are used to create the surgical splint which is used during surgery to ensure the facial bones are positioned correctly.

The modified models can also be used for pre-bending of the generic miniplates used during orthognathic surgery, thus saving time during the procedure (Lin, et al., 2018)

What are the advantages of 3D printing in planning orthognathic surgery?

3D printing in orthognathic surgery can be utilised at a number of levels, whether it is simply the printing of models to replace stone models, or even for fabrication of the surgical splint used during the procedure. The advantages of 3D printing in orthognathic surgery include (Hammoudeh, et al., 2018) (Kim, et al., 2011) (Cousley & Turner, 2014) (Lin, et al., 2018) (Evans & Desai, 2016):

- Digital planning and printing is drastically less time consuming.

- Fewer specialised multi-disciplinary team members for the pre-surgical workup and splint fabrication.

- Increased accuracy of presurgical workup and splint as there are fewer steps requiring human intervention and therefore decreased risk of human error.

- Improved predictability out surgical outcomes.

- Reduction in possible laboratory delays.

- Increased surgical safety due to:

- Reduced exposure to ionising radiation by reducing the need to rely on cephalometrics required for tracing.

- Easier diagnosis of malocclusion.

- The ability to review surgical steps and plan essential pre- and peri-operative steps.

- Reduced surgical operative time.

- Removal of need for traditional acrylic splints which can warp.

- Accurate, patient-specific models are vital for clinician-patient communication.

The future of 3D printing in treatment planning

The advantages of 3D printing in orthognathic surgery have been outlined previously. There are continuous developments within the field with a movement towards virtual surgical planning, which will require clinicians to work with colleagues who have CAD/CAM experience.

Taking this a step further may even see virtual model surgery surpass the need for any traditional models as clinicians are able to undertake digital scanning and modelling with software to produce accurate analysis prior to surgery (Hammoudeh, et al., 2018). Where strict guidance can be followed, biomedical models fit for use in the human body can be produced and the next developments could see 3D printing in orthognathic surgery to produce the fixation plates specific to an individual patient as well as producing cutting guides and spacers becoming more affordable and more widely available (Lin, et al., 2018).

At Medimodel we help clinicians establish more effective visualisation and planning prior to surgeries. We can also help with the application of scan data such as producing models and surgical planning. Phone us on +44 (0) 117 325 8171 or reach out to us at [email protected] if you wish to discuss your case with us.

Bibliography

Cousley, R. & Turner, M., 2014. Digital model planning and computerized fabrication of orthognathic surgery wafers.. Journal of Orthodontics, 41(1), pp. 38-45.

Dawood, A., Marti Marti, B. & al, e., 2015. 3D printing in dentistry. British Dental Journal, Volume 219, pp. 521-529.

Evans, J. & Desai, P., 2016. Applications for three-dimensional printing in dentistry. Decisions in Dentistry, Volume 1, pp. 28-30,32.

Hammoudeh, J., Howell, L. & all, e., 2018. Current Status of Surgical Planning for Orthognathic Surgery: Traditional methods vs 3D Surgical Planning. Plat Reconst Surg Glob Open, Volume 3, p. e307.

Katiyar, R., Singha, G. & al, e., 2018. Surgical–orthodontic treatment of a skeletal class III malocclusion. Natle J Maxillofac Surg, Volume 1, pp. 143-149.

Kim, B.C., Lee, C. & al., e., 2011. Clinical experiences of digital model surgery and the rapid prototyped wafer for maxillary orthognathic surgery.. Oral Surg Oral Med Oral Pathol Oral Radiol Endod, Volume 111, pp. 278-285.

Lin, H., Lonic, D. & Lo, L., 2018. 3D printing in orthognathic surgery – a literature review. Journal of the Formosan Medical Association, Volume 117, pp. 547-558.