The DICOM file process

Convert a DICOM file to a 3d model

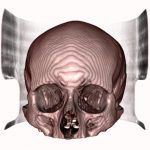

In this post we explain how we convert a DICOM file to a 3d model. DICOM stands for Digital Imaging and Communications in Medicine and is a standard for handling, storing, printing, and transmitting information in medical imaging. In this short case study we show how we can convert DICOM files from a CT (computed tomography) scan of a patient awaiting dental surgery into an STL file which we can then 3D print. In this case the surgeon needed a 3D print to help visualise the surgery site and plan the procedure. This process allows surgeons to experience an extra dimension when planning such procedures, and the ability to fully manipulate and explore the area of interest in the real world before commencing surgery. The DICOM file exists as a series of many hundreds of cross-sectional slices taken through an area of the patient’s body via a CT scan; the combination of all of these 2D cross-sections creates a 3 dimensional volume which can be processed into a file suitable for 3D printing. The process allows for separate models to be generated and/or points of interest isolated according to density e.g. soft tissue, cartilage, bone and enamel.

A DICOM file is a series of images generated from a CT scan and consists of many hundreds of individual slices of a patient’s body

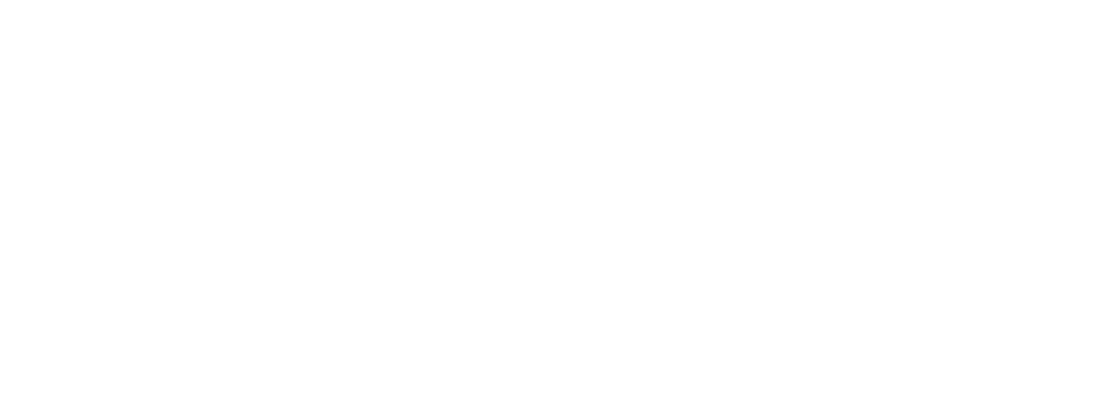

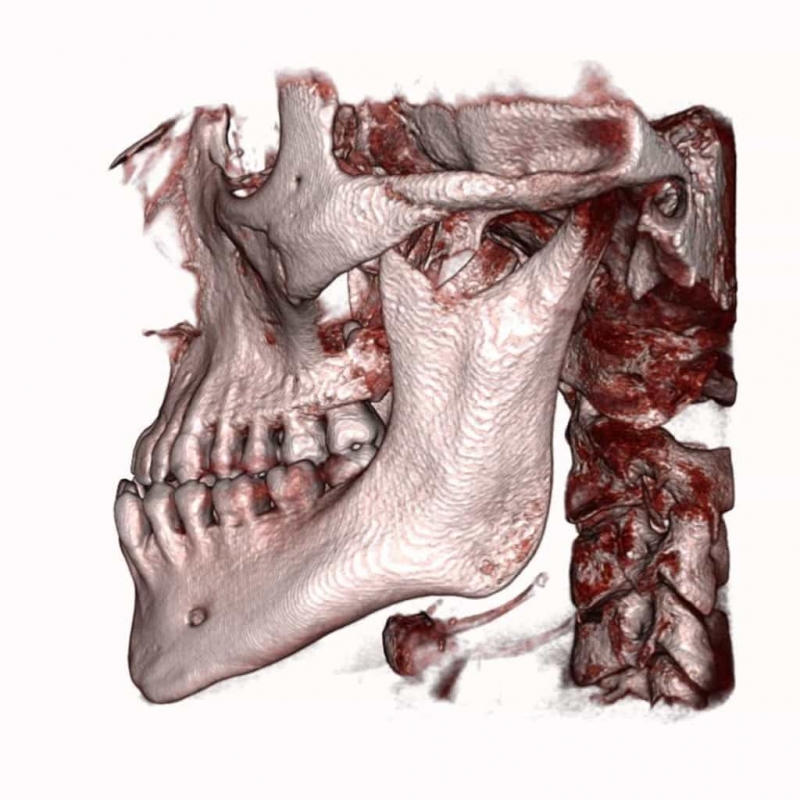

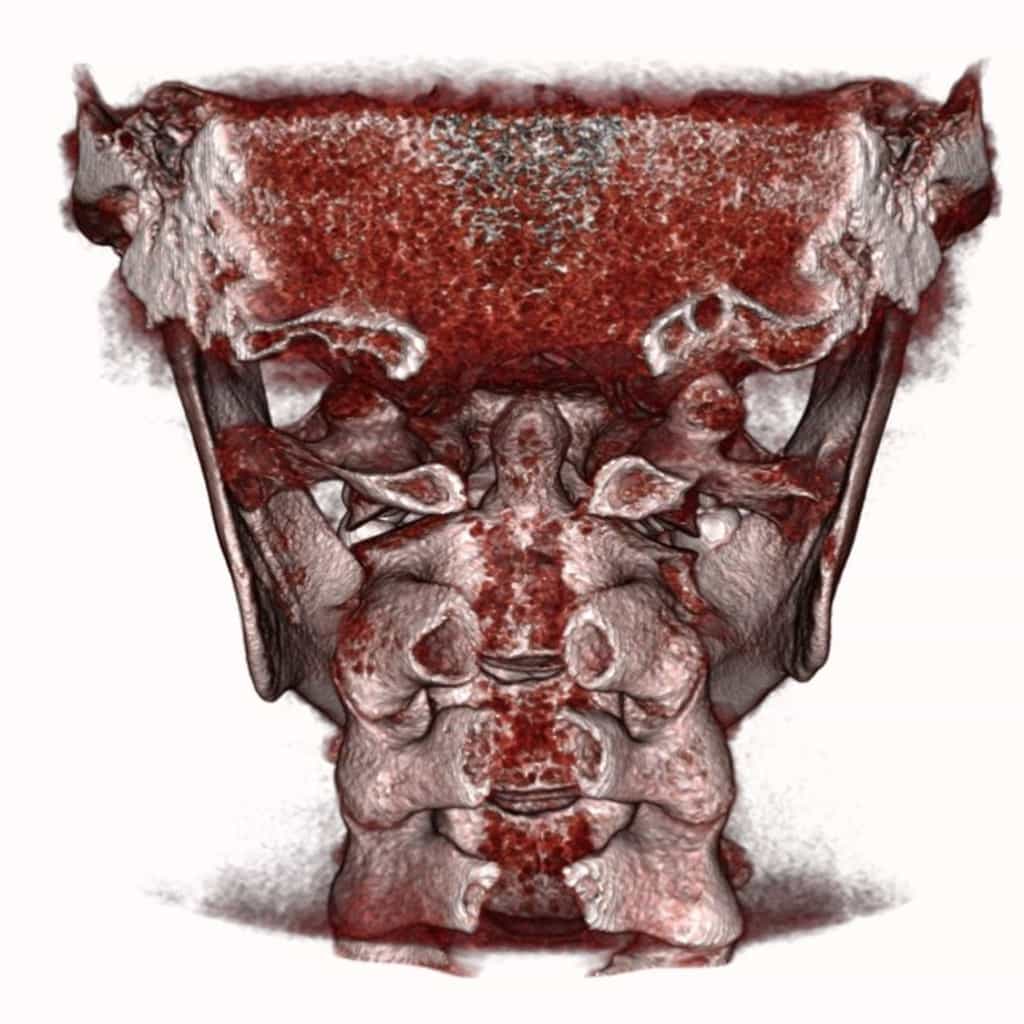

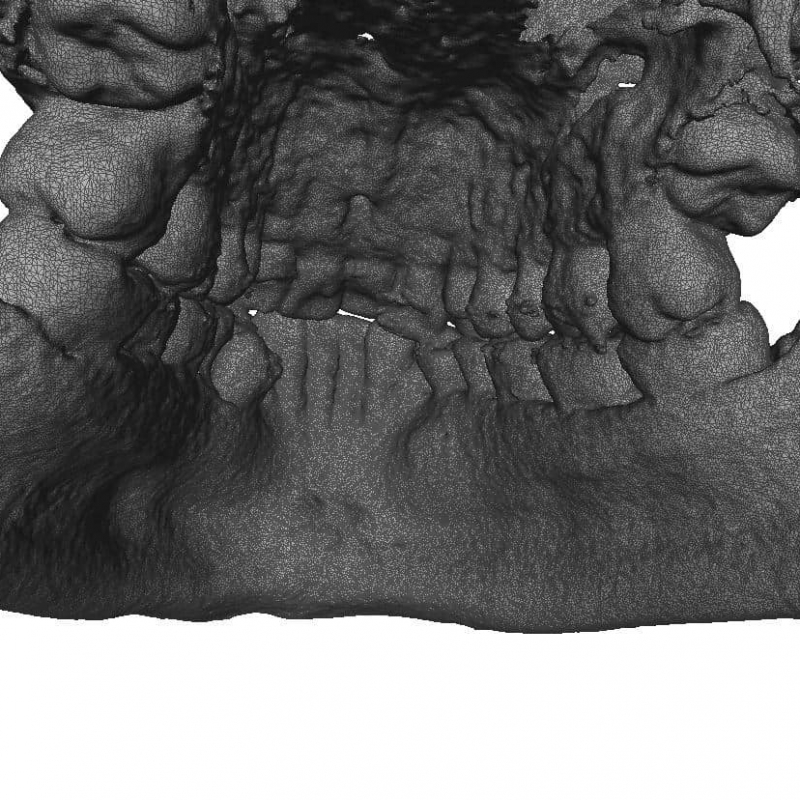

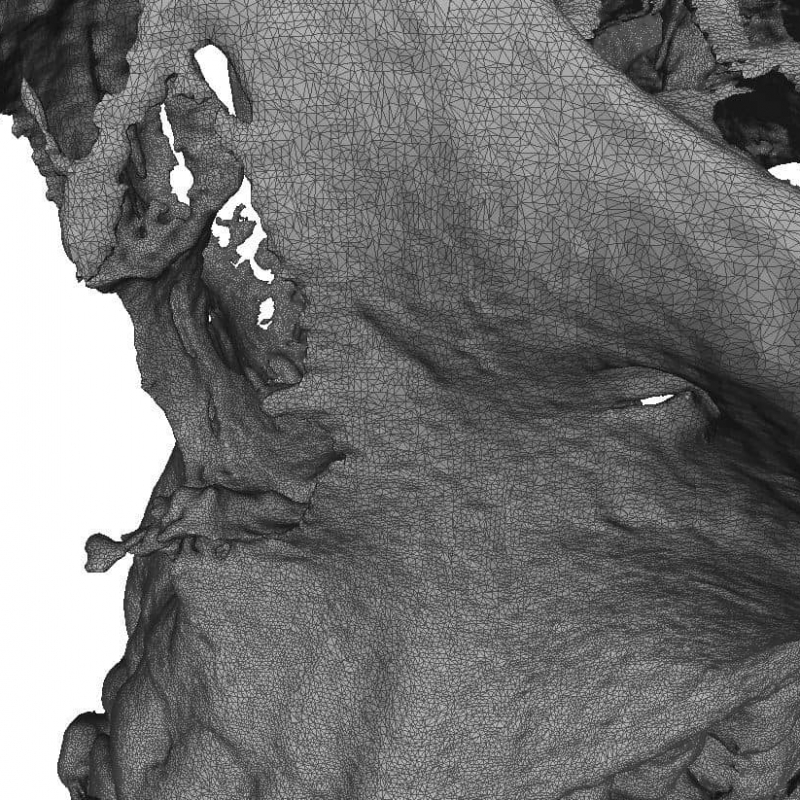

The 3D data extracted from the DICOM file

The 3D data from the DICOM file is processed in order to extract the areas of interest, which in this case is just hard bone and enamel.

The DICOM data can be isolated to show only the areas of interest, these include soft tissue, bone and tooth enamel and can be recombined to print different tissue in different colours.

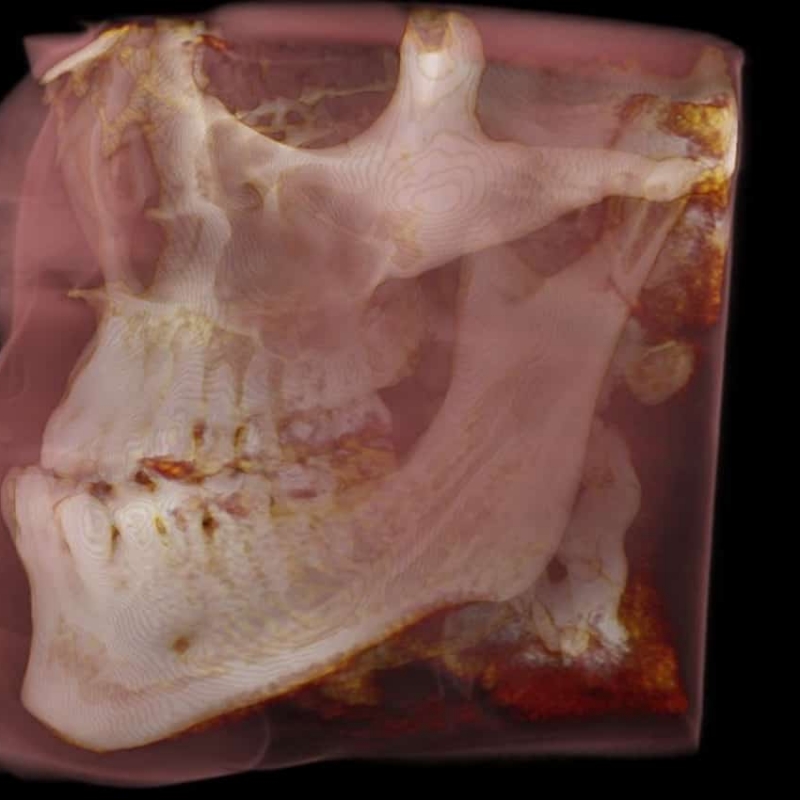

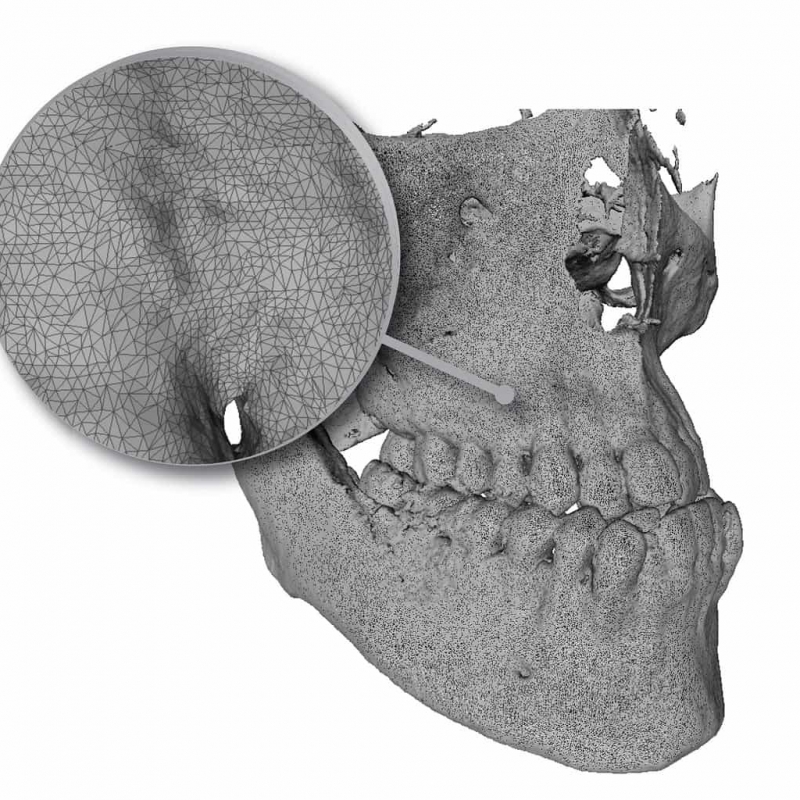

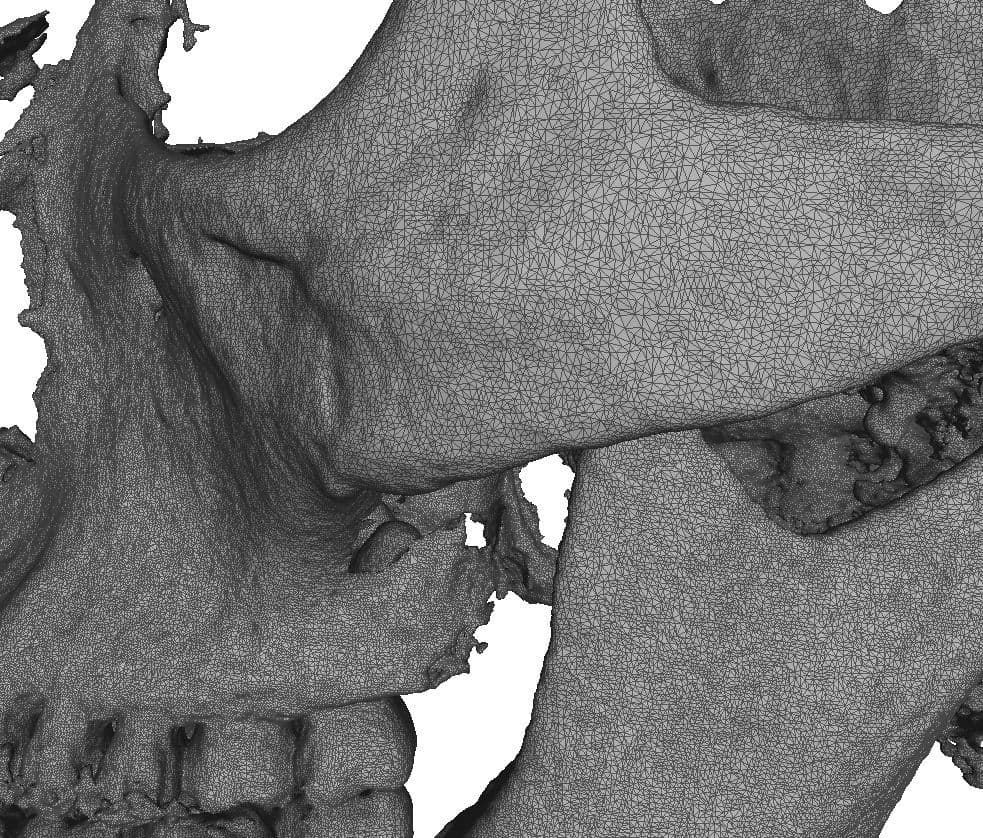

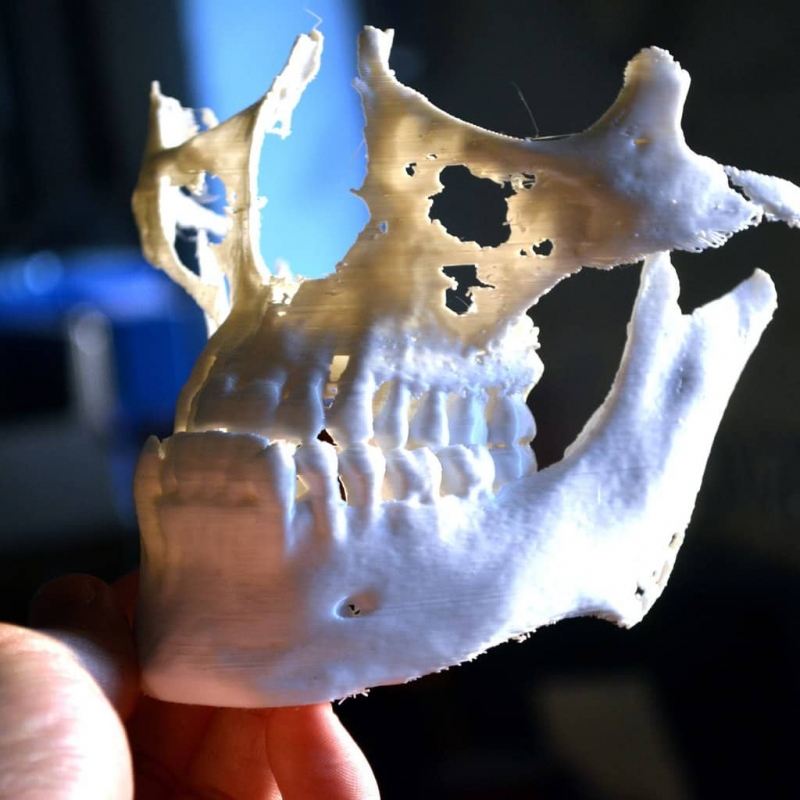

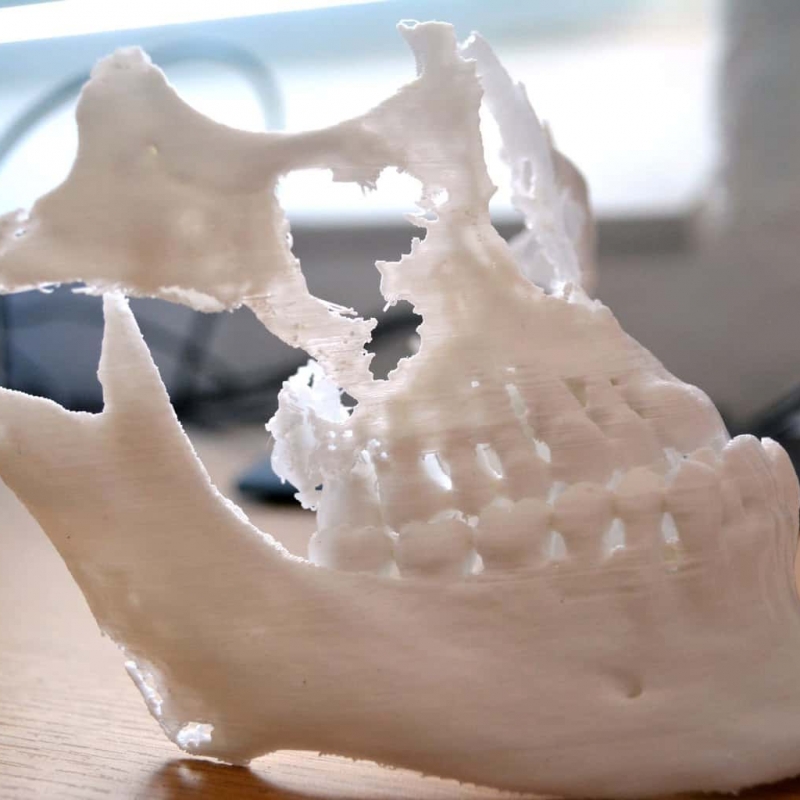

The STL files ready for printing

By converting the DICOM file to the universally accepted STL format we are able to produce this model on any commercially available 3D printing or additive manufacturing system. It also allows the integration with other CAD systems and enables the development of prostheses or implants which may in turn also be produced through additive layer manufacturing techniques. By using this open format there is a lot of flexibility in the secondary processes that are available.

An STL file is a triangle mesh and is most universally accepted file type used in 3D printing.

The benefits of printing CT scan models

Clinicians like to use 3D prints of CT scan imagery as a physical reference prior to surgery to enable more effective visualisation and planning. Being able to hold the physical body part the clinician will be operating on gives an increased degree of understanding and insight into the surgery site. It also presents an array of opportunities for generating prostheses and implants for reconstructive surgery using CAD modelling and other digital techniques. This means that these prostheses can be designed and built prior to any surgery being carried out. The benefits are that not only can the surgeon touch and feel the surgery site, but they also have the bespoke prostheses on hand to refer to prior to surgery.

3D printed models of CT scans are an effective way to aid the visualisation and planning of surgery and as a reference for teaching. There are a large range of materials available to suit the required level of detail and quality, from robust teaching aids and drill guides to highly accurate models for planning.

Interested in finding out more?

WORKING WITH DICOM IMAGES FROM CT AND MRI SCAN DATA WE HELP DENTAL, MEDICAL AND VETERINARY PRACTITIONERS ACROSS THE NHS AND PRIVATE CLINICS BY PRODUCING TRUE TO LIFE 3D PRINTED MODELS OF PATIENT ANATOMY TO INFORM PROCEDURES AND REDUCE RISK.

We are currently working with a number of surgeons to explore new applications. Convert DICOM file to 3d model. If you are interested in finding out more or would like to send us a DICOM file please give us a call on 0117 325 8171 or email [email protected].