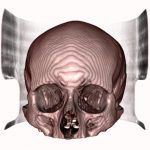

3D printing DICOM files

Many clinicians like to use 3D prints of CT scan data as a physical reference prior to surgery to enable more effective visualisation and planning. Being able to hold the physical piece of anatomy the clinician will be operating on gives an increased degree of understanding and insight. It also presents an array of opportunities for generating prostheses and implants for reconstructive surgery using CAD modelling and other digital techniques. These prostheses can be designed and built prior to surgery being carried out so that clinicians can touch and feel the surgery site and also have bespoke prostheses on hand to refer to prior to surgery.

3D printing processes

Polyjet – When 3D printing DICOM files, Polyjet is our most aesthetic option; it offers very high resolution, detail and accuracy and allows for extremely fine features to be reproduced. Different areas of interest may also be isolated and printed in different materials. This can be particularly useful in highlighting critical areas such as nerves.

FDM – FDM offers lower resolution and fine details but is much tougher, it has a lower cost and is ideally suited to cutting, drilling and filling.

Flexible materials

We can 3D print in flexible materials to simulate tissue and flexible joints and mix materials of varying hardness within a single 3D print. This is useful for simulating bone, cartilage and soft tissue in a single model. Materials range in hardness from a soft silicone to a car tyre and have an elasticity at break of around 250%, ideal for when you need to bend or stretch a model.

Transparent models

Models can be printed in a very high resolution transparent material allowing you to see inside the geometry. We can also combine different segments in different materials so you see one inside the other. For example if you want to highlight blood vessels, they can be printed in a different colour inside of a clear model.