The Advantages of 3D Print in Healthcare

As the world continues to develop and move progressively towards high technology, the old methods and processes are being replaced with advanced systems. One of the latest technologies designed is the 3D printing of results in medical procedures. The medical applications for 3D printing are rapidly expanding and it is likely to revolutionize the healthcare industry.

What is 3D Printing?

The three-dimensional (3D) printing is a manufacturing method wherein objects are made by fusing, solidifying or depositing materials (plastic, metal, ceramics, powders, liquids, living cells) in layers to produce a 3D object. Other terms used include additive manufacturing (AM), rapid prototyping (RP), or solid-free form technology (SFF). There are 3D printers used in this process which are similar to inkjet printers, some use lasers and others extrude molten materials..

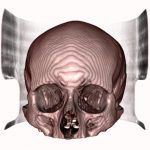

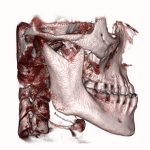

There are around two dozen 3D printing processes which make use of different printer technologies, speeds, resolutions, and hundreds of materials. These technologies can build a 3D object in almost any shape imaginable as defined in a computer-aided design (CAD) file. It is important to note that two-dimensional (2D) radiographic images, such as magnetic resonance imaging (MRI)and computerized tomography (CT) scans, can be converted to digital 3D print files, allowing the creation of complex, customized anatomical, and medical structures.

Here are some of the benefits and advantages of 3D printing in medical applications:

1. Customization and personalization

One of the greatest advantages of 3D printing in medical applications is that it can produce custom-made medical products and equipment. It can help customize prosthetics and implants which can further provide great value for both the patients and the physicians. Custom-made implants, fixtures, and surgical tools can have a positive impact in terms of the time required for surgery, patient recovery time, and the success of the surgery or implant. Moreover, 3D printing can also produce made-to-order drill guides for use in operating rooms.

2. Cost-efficient

Traditional manufacturing methods may still remain cheaper for large-scale production but the cost of 3D printing is becoming more competitive for small production runs. This is especially true for small-sized standard implants or prosthetics like those used for spinal, dental, or craniofacial disorders. The cost to custom-print a 3D object is minimal, with the first item being as inexpensive as the last. This is especially advantageous for companies that have low production volumes or companies that produce parts and products that are highly complex or require frequent modifications.

3. Improved productivity

Using 3D printing means that a product can be made within just a number of hours and will not take days. The quality is also more improved and developed, touching on the areas of resolution, accuracy, reliability, and repeatability of 3D printing technologies.

4. Democratization of design

With the birth of 3D printing in medical applications, there is an accompanied democratization of the design and manufacturing of goods. There is an increase in the array of materials available for use in 3D printing and they are decreasing in cost. This allows more people, including those in the medical fields, to use little more than a 3D printer and their imagination to design and produce novel products for personal or commercial use.

Through 3D printing, data files can also be shared among researchers in a more convenient manner. Rather than trying to reproduce parameters that are described in scientific journals, researchers can access downloadable stereolithography (STL) files that are available in open-source databases. By doing so, they can use a 3D printer to create an exact replica of a medical model or device, allowing the precise sharing of designs.